A high-pressure booster compressor increases or amplifies air pressure coming from an existing system by subjecting it to additional compression stages. Boosting compressed air is often an essential process for applications that need extra power to operate efficiently, like pressure testing and sandblasting. A top-of-the-line booster system can typically deliver pressure up to 10 times greater than most standard compressed air systems.

Adding a booster compressor provides a cost-effective solution to an operation requiring intermittent compressed air capabilities. Compared to operating an entirely separate high-pressure compressed air system, boosters significantly reduce energy costs. At Compressed Air Technologies, we offer various models of high-pressure booster compressors for sale or rent from some of the industry’s most reputable manufacturers.

Compressed Air Technologies is an authorized distributor for several companies that manufacture high-pressure booster compressors. We provide sales, rentals and a complete line of services.

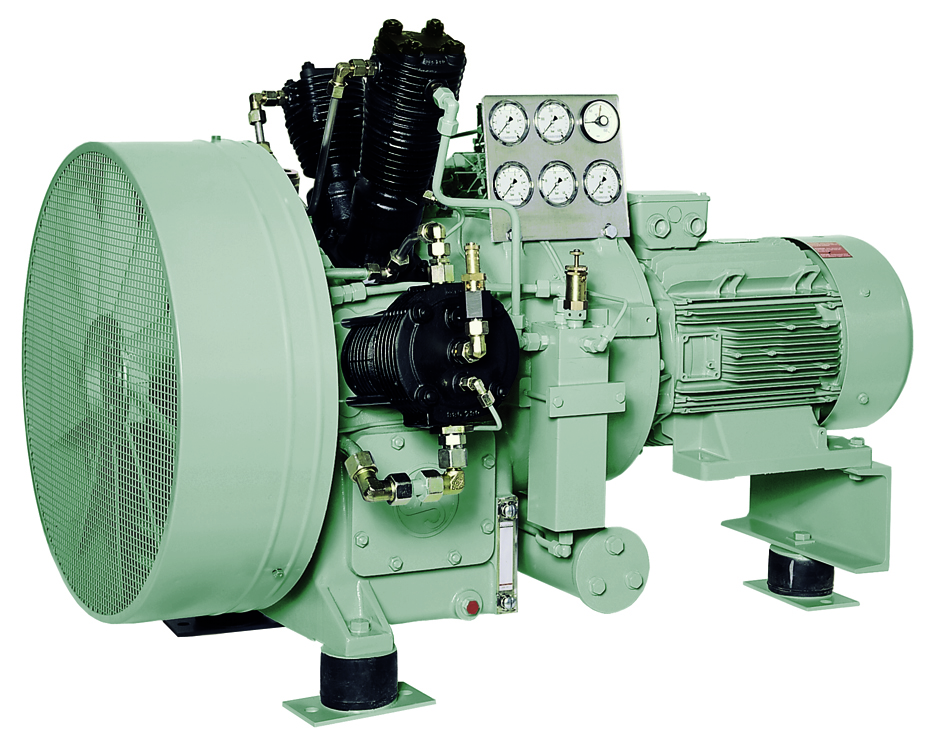

Sauer manufacturers and sells compressors with a rating of up to 500 Bar for use in industries such as shipping, manufacturing and military applications. The Sauer team prides itself on producing high-performance products in addition to top-of-the-class customer service. Quality and reliability are the foundation for all Sauer products.

BAUER designs and builds high-pressure systems for nearly any industrial application across commercial sectors, from aerospace to energy. These air-cooled systems range from 5-125 scfm and are built with 2-, 3-, 4-, and 5-stage compressors. Our cutting-edge technology provides efficient compression for not only air, but nitrogen, natural gas, and noble gases (helium, argon, neon, xenon, and krypton) as well. For special requirements, BAUER can modify a standard package or design a custom package to your specific needs.

There are many industries and processes where compressed air and nitrogen are used at higher pressures of up to 40 bar. PET blowing, laser cutting, pressure tests and abrasive cutting are among some of the widespread processes in which air or nitrogen boosters can be an integral part of the installation. The bstAIR booster can be connected to the plant’s low-pressure network. The standard booster range has a discharge pressure of up to 40 bar, with a flow range of 0.4 m3/min to 3.6 m3/min.

By using a compressor booster for your intermittent needs instead of incorporating a separate high-pressure system, you’ll experience several advantages, including: